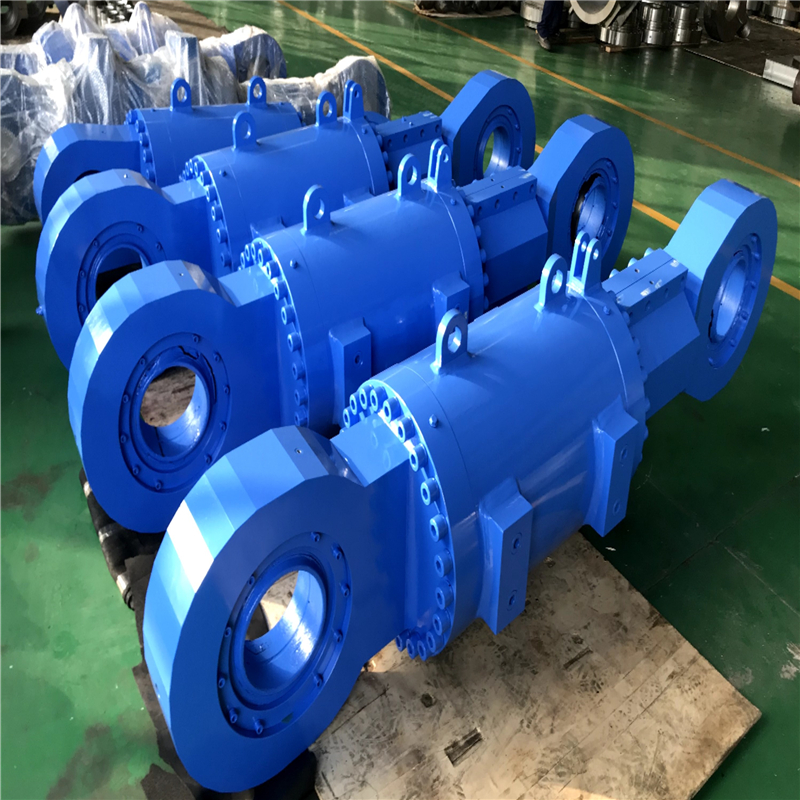

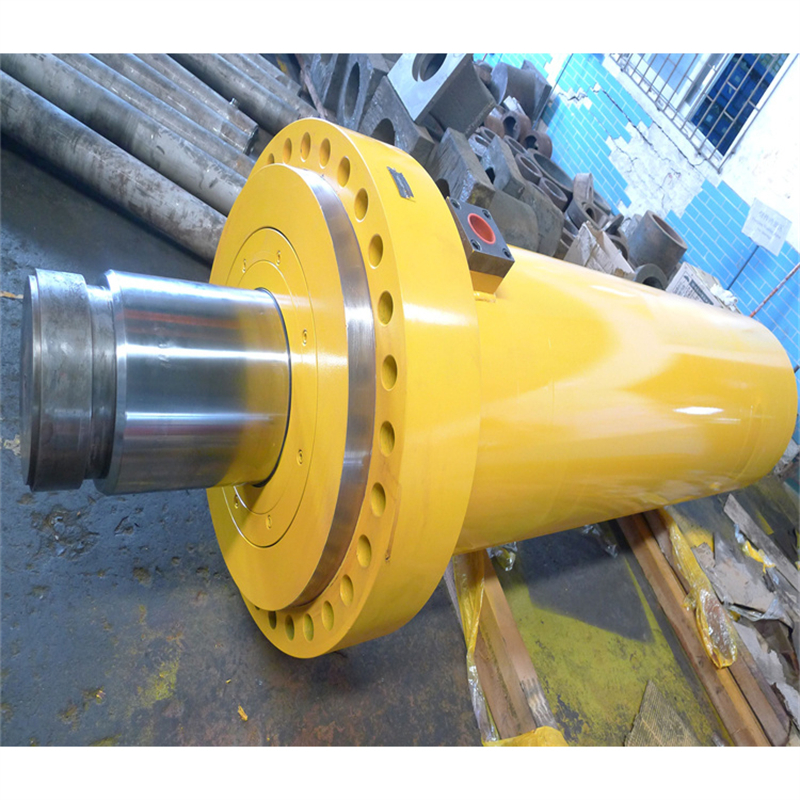

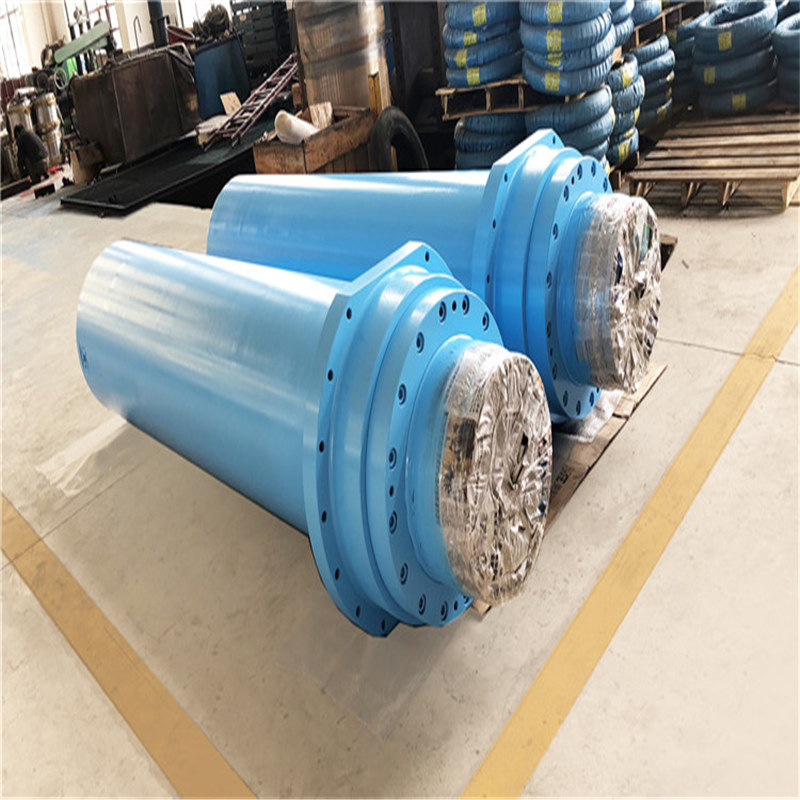

Non-standard Hydraulic Cylinder Body

Introduction:

Hydraulic cylinders are essential components in various industrial applications, providing linear force and motion. While standard hydraulic cylinders are readily available in the market, non-standard hydraulic cylinders are designed to meet specific requirements of unique applications. In this article, we will explore the concept of non-standard hydraulic cylinder bodies and their significance in engineering design.

Definition:

Non-standard hydraulic cylinder bodies refer to the customized or specially designed cylinder bodies that deviate from standard dimensions, configurations, or materials. These cylinders are tailored to meet specific application requirements, such as limited space, extreme operating conditions, or unique load capacities.

Importance of Non-standard Hydraulic Cylinder Bodies:

1. Customization: Non-standard hydraulic cylinder bodies allow engineers to design cylinders that perfectly fit into the available space and meet the specific needs of the application. This customization ensures optimal performance and efficiency.

2. Adaptability: Non-standard cylinders can be designed to withstand extreme operating conditions, such as high temperatures, corrosive environments, or heavy loads. By selecting appropriate materials and coatings, these cylinders can provide reliable performance in challenging environments.

3. Enhanced Performance: Non-standard hydraulic cylinder bodies can be designed to provide higher load capacities, faster speeds, or greater precision compared to standard cylinders. This customization enables engineers to optimize the performance of the hydraulic system for specific applications.

4. Cost-effectiveness: While non-standard hydraulic cylinders may require additional design and manufacturing efforts, they can often result in cost savings in the long run. By tailoring the cylinder to the application's requirements, unnecessary features or components can be eliminated, reducing overall costs.

Design Considerations:

When designing non-standard hydraulic cylinder bodies, several factors need to be considered:

1. Application Requirements: Understanding the specific needs of the application, such as load capacity, stroke length, operating pressure, and environmental conditions, is crucial for designing an effective cylinder body.

2. Space Constraints: Non-standard cylinders are often required when space is limited. Designers must carefully consider the available space and design the cylinder body to fit within the given dimensions.

3. Material Selection: The choice of materials for non-standard cylinder bodies depends on the application's requirements. Factors such as corrosion resistance, temperature resistance, and strength need to be considered when selecting materials.

4. Manufacturing Techniques: Non-standard cylinders may require specialized manufacturing techniques, such as precision machining or welding. Designers must ensure that the chosen manufacturing processes can achieve the desired specifications and quality.

Conclusion:

Non-standard hydraulic cylinder bodies play a vital role in meeting the unique requirements of various industrial applications. By customizing the cylinder design, engineers can optimize performance, adapt to challenging environments, and achieve cost-effectiveness. However, careful consideration of application requirements, space constraints, material selection, and manufacturing techniques is essential for successful design and implementation. As a leading hydraulic technology department, we are committed to providing innovative solutions and expertise in non-standard hydraulic cylinder design.

(This content is from the hydraulic technology department of Gongliang Hydraulic Technology. Please indicate the source if reproduced.)