Title: Introduction to Pressurized Hydraulic Cylinder

Keywords: Pressurized hydraulic cylinder, design, function, components, applications

Introduction:

This article provides an overview of pressurized hydraulic cylinders, their design, components, and applications. The content is sourced from the Engineering Department of Gongliang Hydraulic Technology, and any reproduction must include proper attribution.

Pressurized Hydraulic Cylinder:

A pressurized hydraulic cylinder, also known as a hydraulic actuator, is a mechanical device that converts hydraulic energy into linear motion. It is widely used in various industries, including construction, manufacturing, and transportation, due to its ability to generate high forces and precise control.

Design and Components:

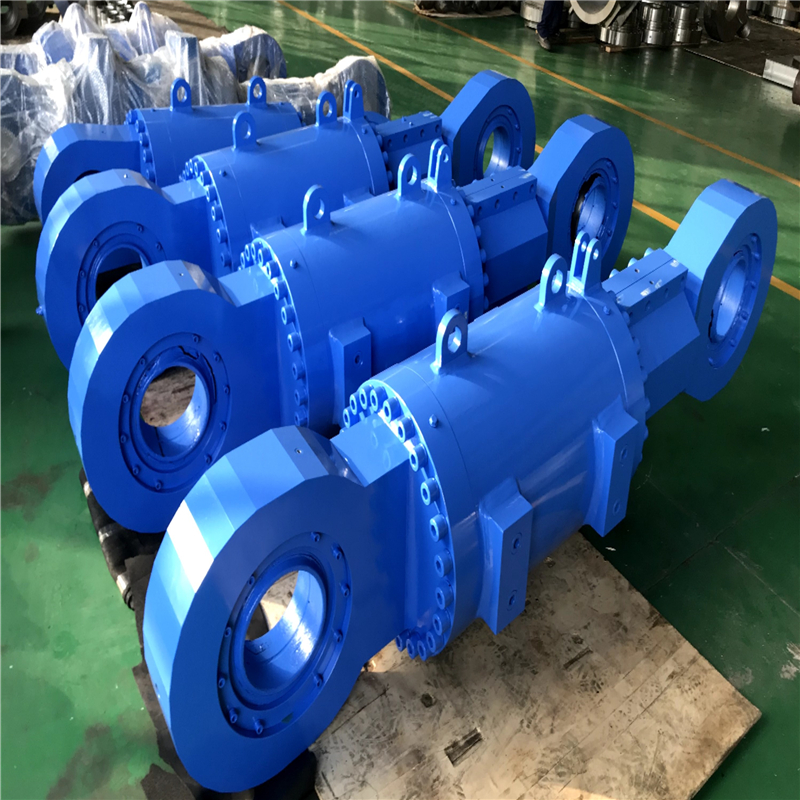

A pressurized hydraulic cylinder consists of several key components, each playing a crucial role in its operation. These components include:

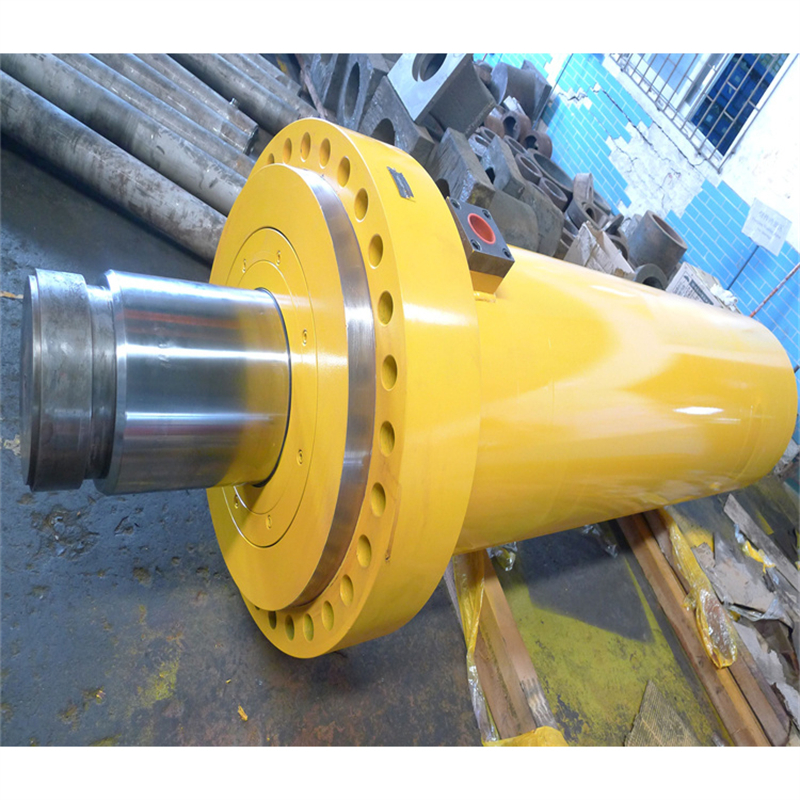

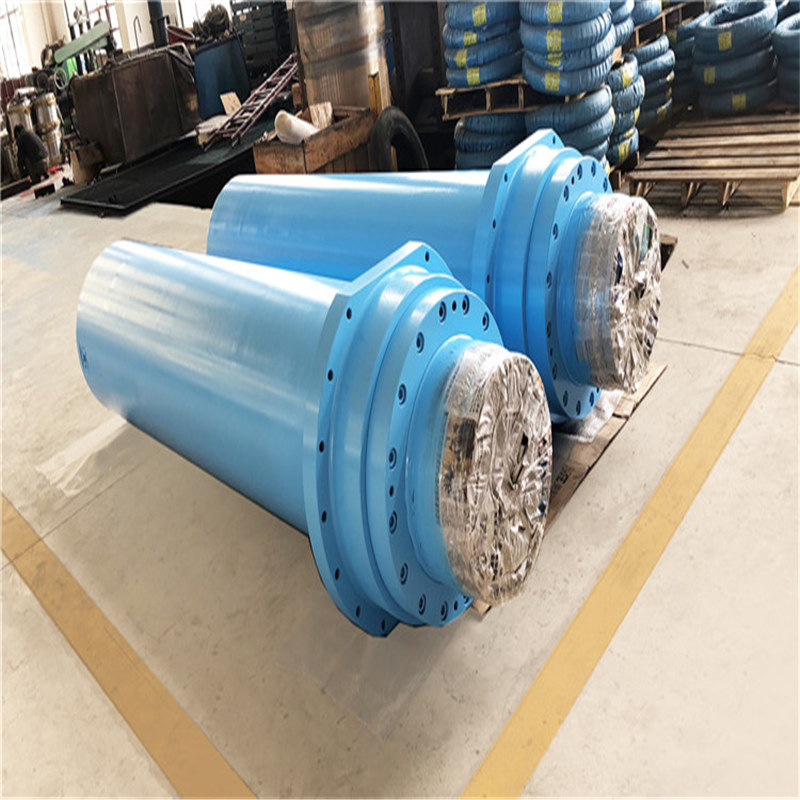

1. Cylinder Barrel: The cylinder barrel is a seamless tube that houses the piston and other internal components. It is typically made of high-strength steel to withstand high pressures.

2. Piston: The piston is a cylindrical component that divides the cylinder barrel into two chambers. It is sealed with piston rings to prevent fluid leakage and ensure efficient operation.

3. Piston Rod: The piston rod connects the piston to the external load. It transmits the force generated by the hydraulic fluid to the desired application.

4. Seals: Seals are essential for preventing fluid leakage between the piston and cylinder barrel. They ensure the efficiency and longevity of the hydraulic cylinder.

5. Hydraulic Fluid: The hydraulic fluid, usually oil-based, is responsible for transmitting pressure and force within the cylinder. It also provides lubrication and cooling for the internal components.

Function and Operation:

The pressurized hydraulic cylinder operates based on Pascal's law, which states that pressure applied to a fluid in a confined space is transmitted equally in all directions. When hydraulic fluid is pumped into one chamber of the cylinder, it exerts pressure on the piston, causing it to move in the desired direction. The movement of the piston is then transmitted through the piston rod to the external load, enabling the desired mechanical action.

Applications:

Pressurized hydraulic cylinders find applications in various industries and equipment, including:

1. Construction Machinery: Hydraulic cylinders are used in excavators, bulldozers, cranes, and other heavy machinery to perform tasks such as lifting, pushing, and digging.

2. Manufacturing Equipment: Hydraulic cylinders are utilized in presses, injection molding machines, and metal forming equipment to provide precise force and control during the manufacturing process.

3. Transportation: Hydraulic cylinders are employed in vehicles such as dump trucks, garbage trucks, and hydraulic lifts to facilitate loading, unloading, and lifting operations.

Conclusion:

Pressurized hydraulic cylinders are essential components in many industrial applications, providing reliable force and precise control. This article has provided an introduction to their design, components, and applications. It is important to acknowledge that this content is sourced from the Engineering Department of Gongliang Hydraulic Technology, and any reproduction must include proper attribution.