小臂油缸英文

Hydraulic Cylinder for Lower Arm

Introduction

Hydraulic cylinders play a crucial role in various industries, including construction, manufacturing, and transportation. These devices convert hydraulic energy into linear mechanical force and motion, making them essential components in many applications. In the field of construction machinery, one common type of hydraulic cylinder is the hydraulic cylinder for the lower arm, also known as the small arm hydraulic cylinder.

Definition and Function

The hydraulic cylinder for the lower arm is a specific type of hydraulic cylinder used in construction machinery, such as excavators and loaders. It is responsible for controlling the movement of the lower arm, which is an important part of the machine's arm system. The lower arm is typically connected to the boom and bucket, allowing the machine to perform various tasks, such as digging, lifting, and loading.

Design Considerations

Designing a hydraulic cylinder for the lower arm requires careful consideration of several factors. These factors include the required force and stroke, the operating pressure, the mounting configuration, and the environmental conditions. The cylinder must be designed to withstand the high forces and pressures involved in construction applications while maintaining smooth and reliable operation.

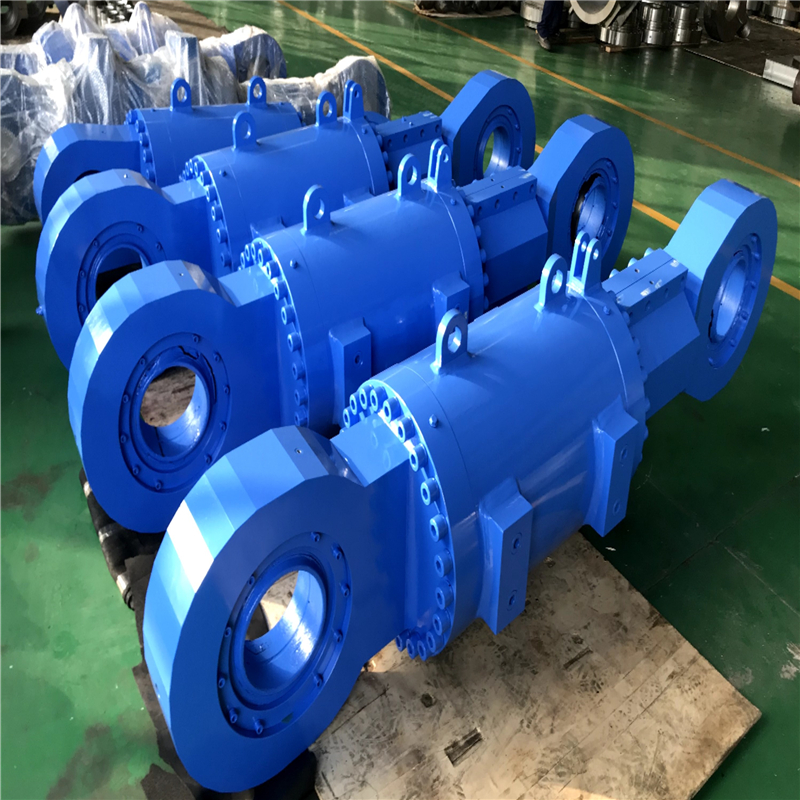

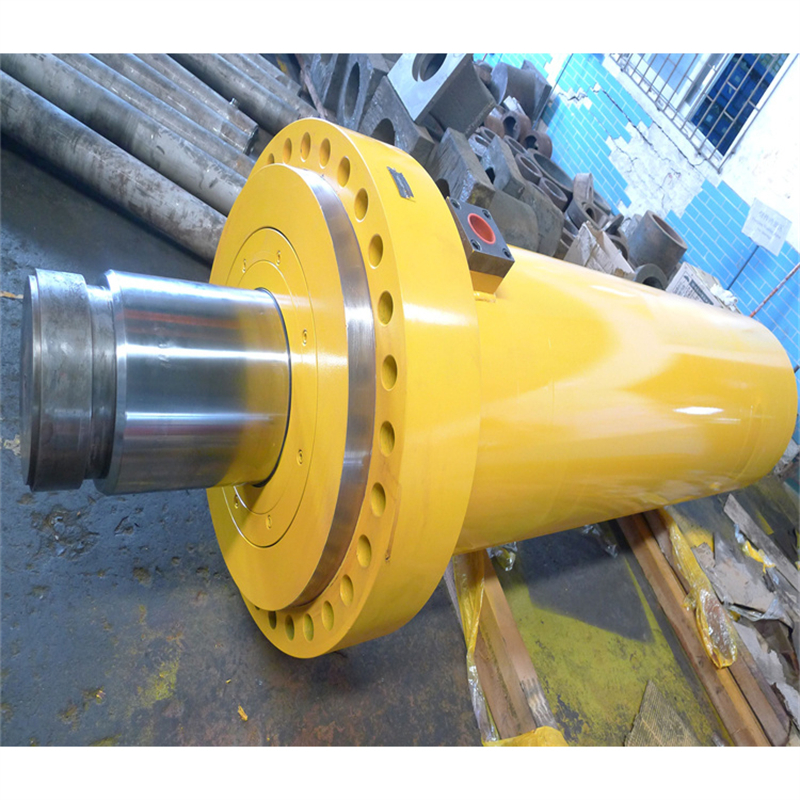

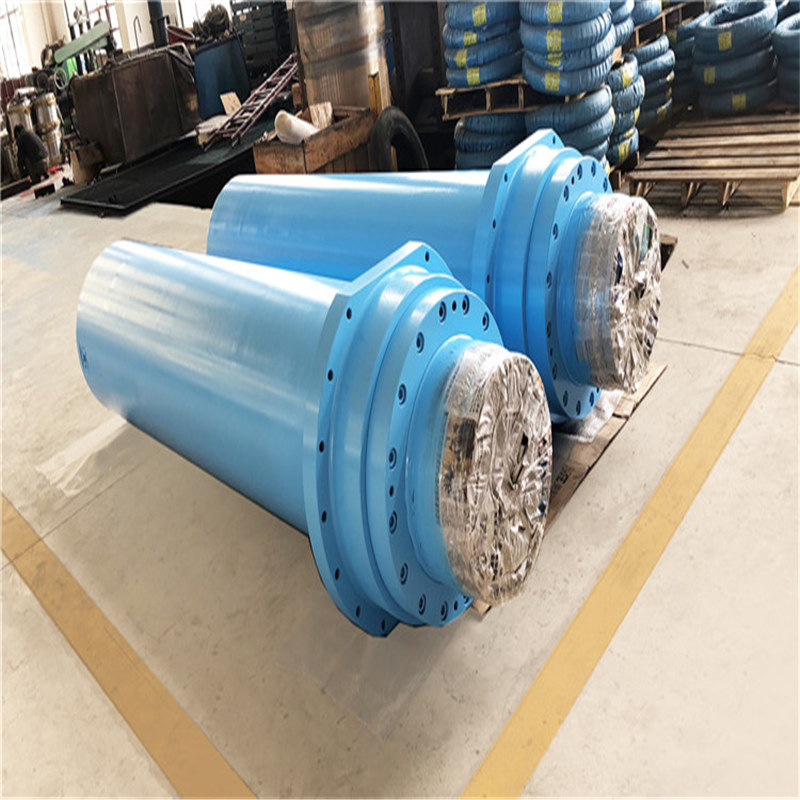

Materials and Construction

Hydraulic cylinders for lower arms are typically made from high-strength steel, such as alloy steel or carbon steel, to ensure durability and resistance to wear and tear. The cylinder barrel is precision machined to provide a smooth surface for the piston seal and prevent leakage. The piston rod is also made from high-strength steel and is chrome-plated to enhance corrosion resistance and reduce friction.

Sealing System

The sealing system of the hydraulic cylinder for the lower arm is critical to its performance and longevity. It must effectively prevent hydraulic fluid leakage and contamination, ensuring smooth operation and minimizing maintenance requirements. The sealing system typically includes piston seals, rod seals, and wiper seals, which are made from high-quality materials such as polyurethane or rubber.

Mounting Configuration

The mounting configuration of the hydraulic cylinder for the lower arm depends on the specific machine and application requirements. Common mounting options include flange mounts, clevis mounts, and trunnion mounts. The mounting configuration must provide secure attachment to the machine while allowing the cylinder to move freely and accommodate the required range of motion.

Maintenance and Troubleshooting

Proper maintenance and regular inspection are essential to ensure the optimal performance and longevity of hydraulic cylinders for lower arms. Routine maintenance tasks include checking for leaks, inspecting seals and rods for wear, and lubricating moving parts. If any issues or malfunctions are detected, troubleshooting should be performed promptly to identify and resolve the problem.

Conclusion

The hydraulic cylinder for the lower arm is a vital component in construction machinery, enabling precise control of the lower arm's movement. Its design and construction must consider factors such as force requirements, operating pressure, mounting configuration, and sealing system. By understanding the importance of this component and implementing proper maintenance practices, construction machinery operators can ensure the reliable and efficient operation of their equipment.

This content is written by the Hydraulic Technology Department of Gongliang Hydraulic Technology. If reproduced, please indicate the source.