油缸英文怎么说?

Hydraulic Cylinder

Introduction:

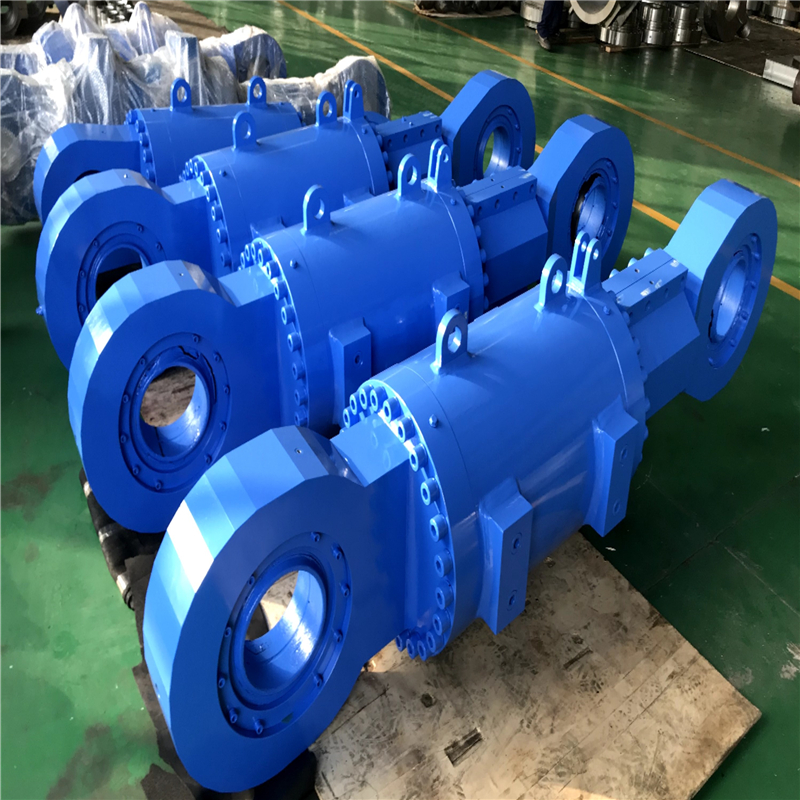

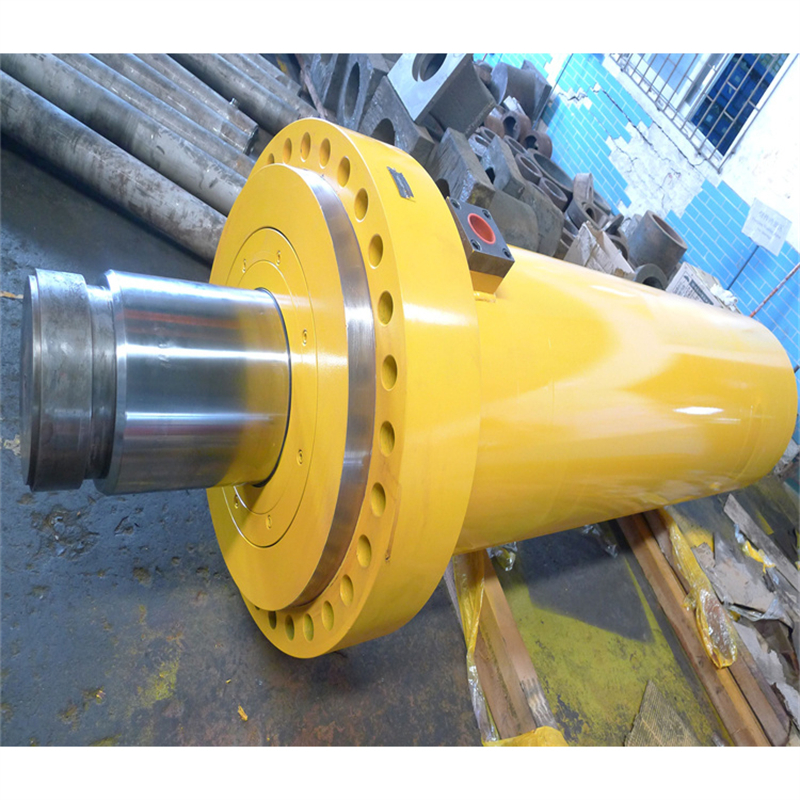

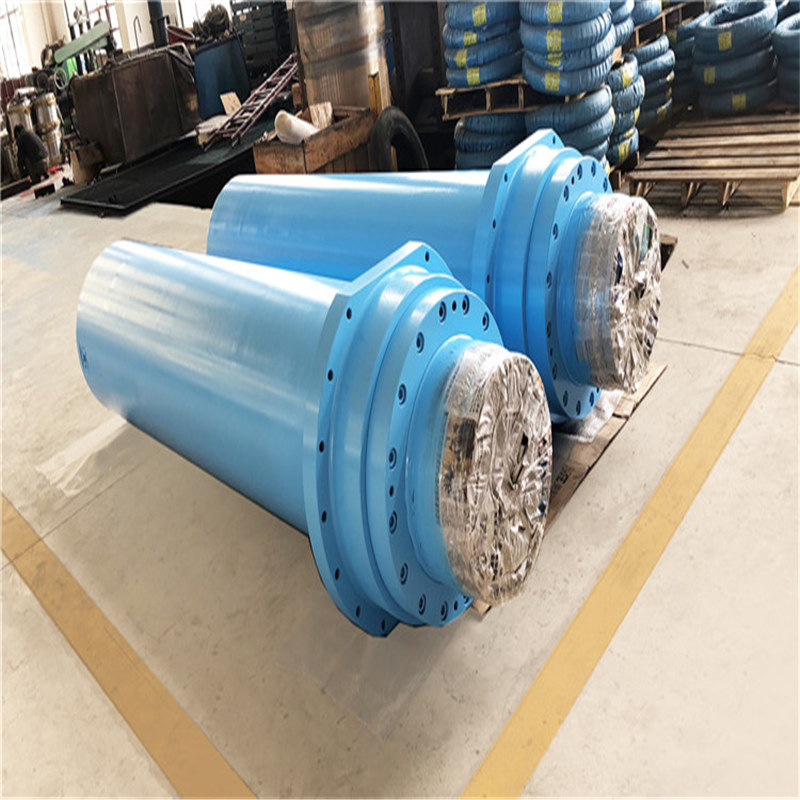

Hydraulic cylinders, also known as oil cylinders, are essential components in hydraulic systems. They convert the energy of pressurized hydraulic fluid into linear motion, providing the force necessary to move heavy loads. Hydraulic cylinders are widely used in various industries, including construction, manufacturing, agriculture, and transportation.

Definition and Function:

A hydraulic cylinder is a mechanical actuator that generates unidirectional force through a piston within a cylindrical housing. It consists of a cylinder barrel, piston, piston rod, and various seals. When hydraulic fluid is pumped into the cylinder, it pushes the piston, causing the piston rod to extend or retract. This linear motion can be used to lift, push, or pull objects.

Design Considerations:

As a highly skilled hydraulic cylinder designer, it is crucial to consider several factors during the design process. These factors include the load requirements, operating conditions, cylinder size, stroke length, and mounting options. The design should ensure optimal performance, durability, and safety.

Load Requirements:

The load requirements determine the force capacity of the hydraulic cylinder. It is essential to accurately calculate the maximum force that the cylinder needs to generate to avoid overloading or underperforming. Factors such as weight, pressure, and acceleration need to be considered.

Operating Conditions:

The operating conditions, including temperature, pressure, and environment, play a significant role in the design of hydraulic cylinders. The materials used for the cylinder barrel, piston, and seals should be selected accordingly to withstand the specific conditions. Proper lubrication and cooling systems should also be considered.

Cylinder Size and Stroke Length:

The cylinder size and stroke length depend on the application and the available space. The size of the cylinder affects its force output and speed. The stroke length determines the maximum distance the piston can travel. It is crucial to balance these factors to achieve the desired performance.

Mounting Options:

Hydraulic cylinders can be mounted in various ways, such as flange, trunnion, clevis, or foot mounting. The mounting option should be chosen based on the application requirements, available space, and load distribution. Proper alignment and support are essential for the cylinder's stability and longevity.

Conclusion:

In conclusion, a hydraulic cylinder, also known as an oil cylinder, is a vital component in hydraulic systems. It converts hydraulic energy into linear motion, providing the force necessary to move heavy loads. As a skilled hydraulic cylinder designer, it is crucial to consider factors such as load requirements, operating conditions, cylinder size, stroke length, and mounting options. By carefully considering these factors, a well-designed hydraulic cylinder can ensure optimal performance, durability, and safety.

This content is written by the Hydraulic Technology Department of Gongliang Hydraulic Technology. If reproduced, please indicate the source.